An autoclave is essentially a chamber that uses steam to sterilize products. Products placed within an autoclave are subjected to increased temperature and pressure as determined by the user. This device has a broad range of use cases across different industries: autoclaves in the medical field are typically referred to as sterilizers, while the R&D, testing, and quality industries call the chambers autoclaves. Because of the multitude of use cases, different autoclaves feature different functions and technologies such as vacuums or electric boilers.

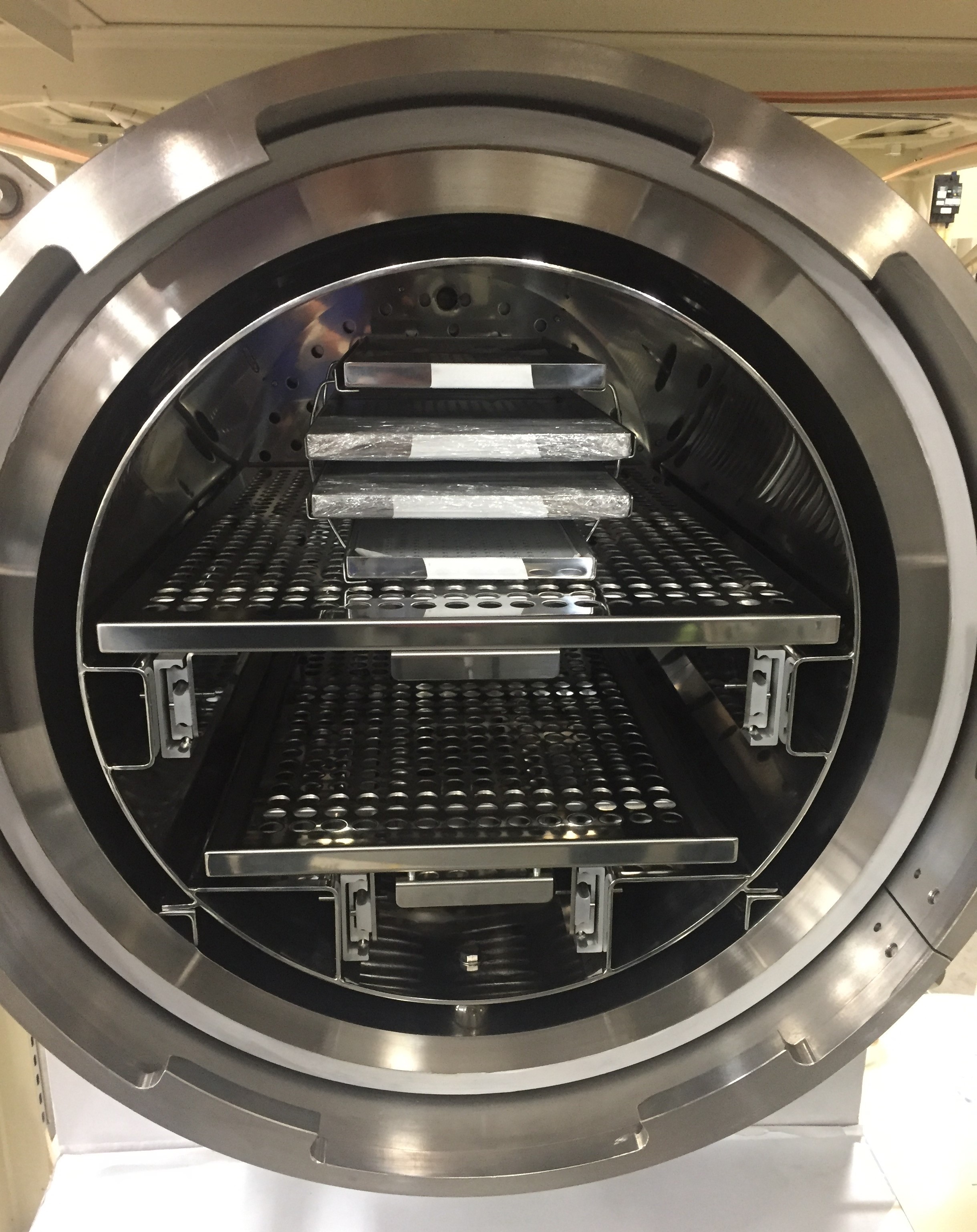

While specialized autoclaves may have extra steps or features, all will have a basic set of components: the chamber, the controls system, the thermostatic trap, the safety valve, and the waste-water cooling system. Sterilization occurs within the chamber which must be resilient to very high temperature and pressure. The controls system allows users to configure the chamber, and will typically interface with a computer for user input and data recording. The thermostatic trap siphons air and water condensate from the chamber, and the safety valve allows pressure to be relieved should there be a mechanical or programming error. The waste-water cooling system rejects heat from condensate post-sterilization to a suitable temperature for draining to coincide with legal requirements.

An autoclave for defoaming LCD panels is a specialized chamber with a specific purpose. This chamber is designed to remove air bubbles from underneath LCD panels of display devices through the use of controlled temperature and pressure. In LCD display production, air bubbles may be present during the process of attaching the polarizing plate to the display; by defoaming the panel, these air bubbles can be removed to lower defect count and increase product quality post-manufacture. This type of autoclave is especially significant because of the broad use of devices with LCD panels such as televisions, monitors, and countless machinery that feature an LCD display.

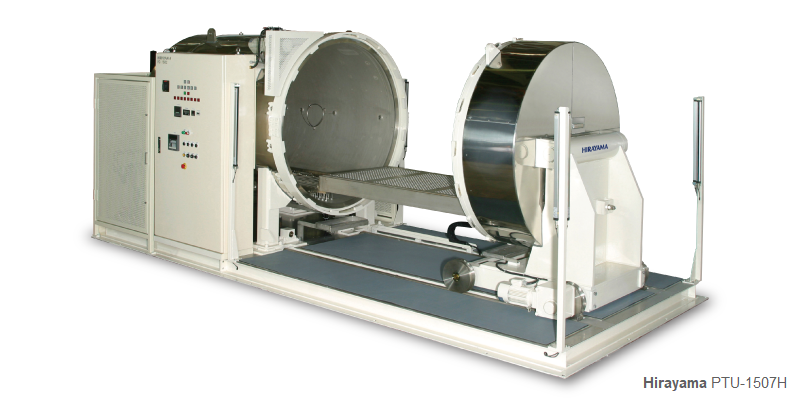

Relia Test Labs utilizes a large cylindrical autoclave for defoaming LCD panels with a chamber diameter of 1.4 m and depth of 2.4 m, resulting in a volume of 3695 L (130.5 ft3). The working temperature range is 50°C to 80°C (±5°C) and the working pressure range is 0.05 to 0.69 MPa (±0.01 MPa). The temperature is adjusted using a PID controller and SSR drive system, and the pressure with a motor valve with two-point measurement data. This chamber features many safety devices such as over-heat and over-pressure prevention, a pressure safety valve, lid-locking, and more.

Several industries benefit from the use of LCD Autoclaves, the most significant being the mobile phone industry. Smartphone manufacturers are implementing cutting edge technologies into their products' displays such as organic LEDs and folding displays, and maintaining a high level of quality is important for staying above their competition. Another major use case for LCD Autoclaves is for automotive infotainment displays. These products are specifically designed for individual vehicles, and must be able to withstand higher temperature and humidity conditions than typical displays. Computer hardware manufacturers that build desktop monitors as well as TV manufacturers also use LCD Autoclaves for making their respective products.

Contact Relia Test Labs for assistance with finding the right LCD Defoaming Autoclave for your testing requirements.

Relia Test Labs is accredited with the ISO/IEC 17025 testing and calibration laboratories standard, making us an attractive solution for your testing needs in the heart of the Silicon Valley.