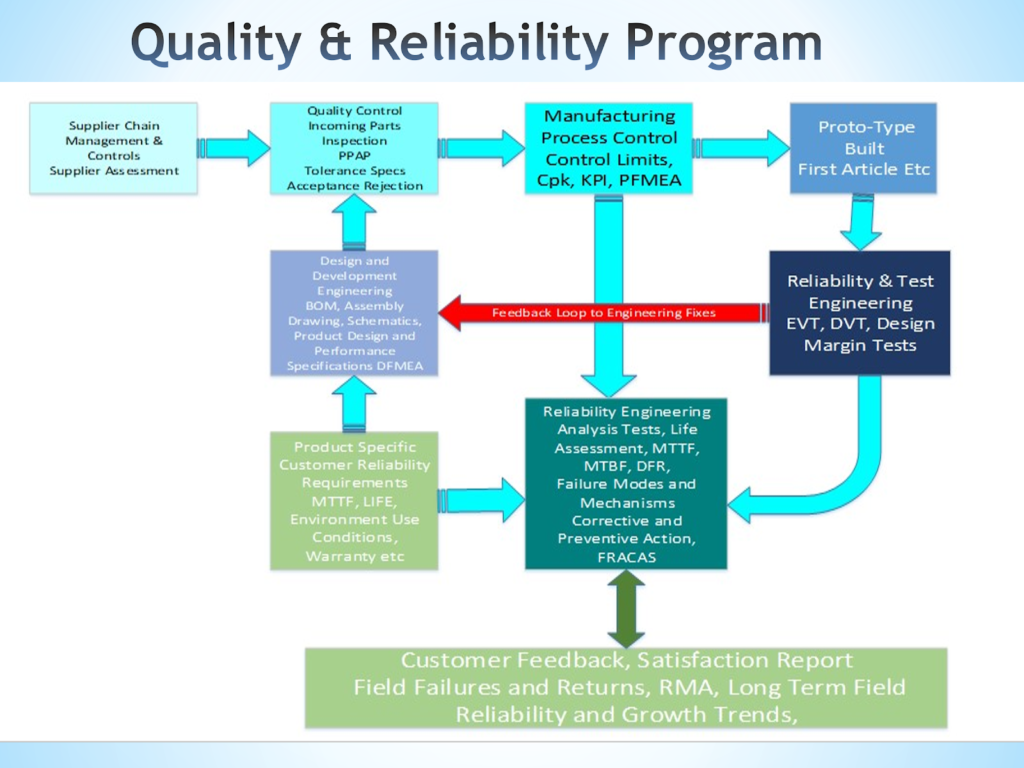

A comprehensive reliability program must be integrated with several phases and functions of a product development and with an NPI program as shown in the diagram above.

The reliability of a product is affected by one or all the attributes of product development and shipment.

As shown in the diagram: The following attributes must be integrated and understood to make a viable, robust, and reliable product with the lowest field failure rate, highest standards of quality and reliability and sustainable field support to obsolescence in the field.

A good reliability program consists of some or all the following attributes:

- Supply chain management with a good, reputable, and dependable supplier who can support the required shipment volume with higher quality such as Quality Level 2 and above to support the program.

- A comprehensive, effective, and an efficient Quality Management System (QMS). Qualified to secure all ISO certifications including ISO-9001 2015.

- Manufacturing Process Controls with SPC in place to monitor and control all aspects of quality and reliability that may adversely affect field product reliability.

- Design engineering and development inputs and selection of components with sufficient design margin and robustness impacts the behaviors of the products in the field. The application conditions, environment, stresses and magnitudes and stress types will impact the field reliability of a product.

- A FAIR program with approval and contingencies must be in place for CTP, CTQ, and FRACAS for support and allow the first product to be reviewed with approval for First Article Inspection and Review Processes.

- A reliability and qualification plan should be in place to test the product and approve under EVT, DVT, DMT, and PVT programs. The product must undergo several levels and stages of testing prior to full volume production and shipment.

- PFMEA and DFMEA plans to validate product and process reliability.

- In the end, reliability tests and analysis provide a final step to understand the limitation of the product functionality and performance over a long period of time.

- An Ongoing Reliability (ORT) and Reliability Demonstration Test (RDT) is equally important. A regular ORT and/or RDT plan with statistical valid sampling plan is key to monitor design performance shifts, production or process shifts and controls, and keep a short- and long-term pulse on the product and customer satisfaction feedback.

- Burn-in. Life Tests and Accelerated Life Tests combined with HALT and HASS may be other aspects to support the Reliability and Quality of a product.

- The last and the most important aspect of such a program requires feedback from the customers that documents success and failures from production to shipment to installation, full commissioning, functional performance, and monitoring to obsolescence.