What is a Burn-In test?

Burn-in testing places devices in high stress environment. The stress conditions that are applied to devices during burn-in are an effective method of aging the devices. In particular, burn-in testing is used to check for internal metal migration or metal expansion that can effect device operation.

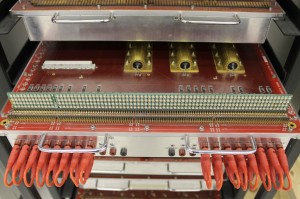

Devices are placed in burn-in boards which are built from high temperature tolerant material that can withstand constant temperature exposures of up to 150°C. The boards are then placed into the burn-in chambers. A voltage bias higher than the nominal voltage level is applied to the devices in order to add additional stress during this test. The test is performed at 125°C for 168 hours.

ReliaTest Labs designs and manufactures burn-in systems including high performance thermal chambers, Burn-In boards, driver boards, and system software. It includes full-service Burn-In Test capabilities to enable qualification of devices/products at different temperatures with simultaneous electrical stimulus.

JEDEC Standard JESD22-A108 as well as other industry and customer specific standards are implemented.