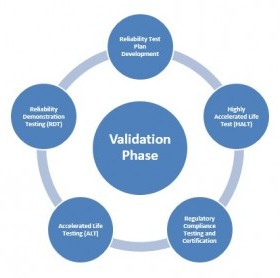

Building margin in the design is a key aspect of a good design. In order to verify the level of margin, HALT can be performed to determine

what is the design susceptibility to conditions above design specs where the margins are tested. The goal is how much design can be stressed to determine its destruct limits, which are above the standard operating limits. It includes various types of conditions such as hot, cold, vibration, voltage margining and combinations of these tests. The inputs to HALT could be stress-de-rating analysis, FMEA/FMECA and thermal simulations. The HALT profile & test results are used as an input to Highly Accelerated Stress Screen (HASS).

- Custom HALT Plan

- HALT execution which includes testing, monitoring and the final report

- Design for compliance

- Compliance test execution which includes monitoring and the final report

- Full certification

- Custom ALT Plan

- ALT execution which includes testing, monitoring and the final report

- Reliability Demonstration Plan

- RDT execution which includes testing, monitoring and the final report